In 1955, a simple idea transformed into a movement—one that would redefine how the world works at height.

What began in a Southern California factory as a spin-off innovation from rescue hoists has become a global name in suspended access. In 2025, Sky Climber® celebrates 70 years of engineering excellence, industry leadership, and a steadfast commitment to safety and service.

It’s more than a milestone. It’s a testament to the people, partnerships, and progress that have elevated Sky Climber from a pioneering product line to a global brand synonymous with trust at height.

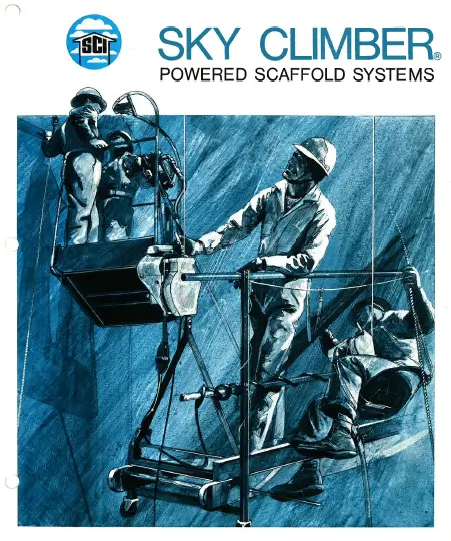

From hoists and swing stages to custom-engineered solutions and permanent systems, Sky Climber has spent seven decades building safer, smarter ways to work at height.

Western Gear Corporation (Lynwood, California)

From Rescue Hoists to a New Industry

Sky Climber’s roots trace back to Western Gear Corporation, founded in San Francisco in 1888 by the Banan family. The company provided precision gearing solutions for everything from San Francisco’s cable cars to fighter jets and naval vessels.

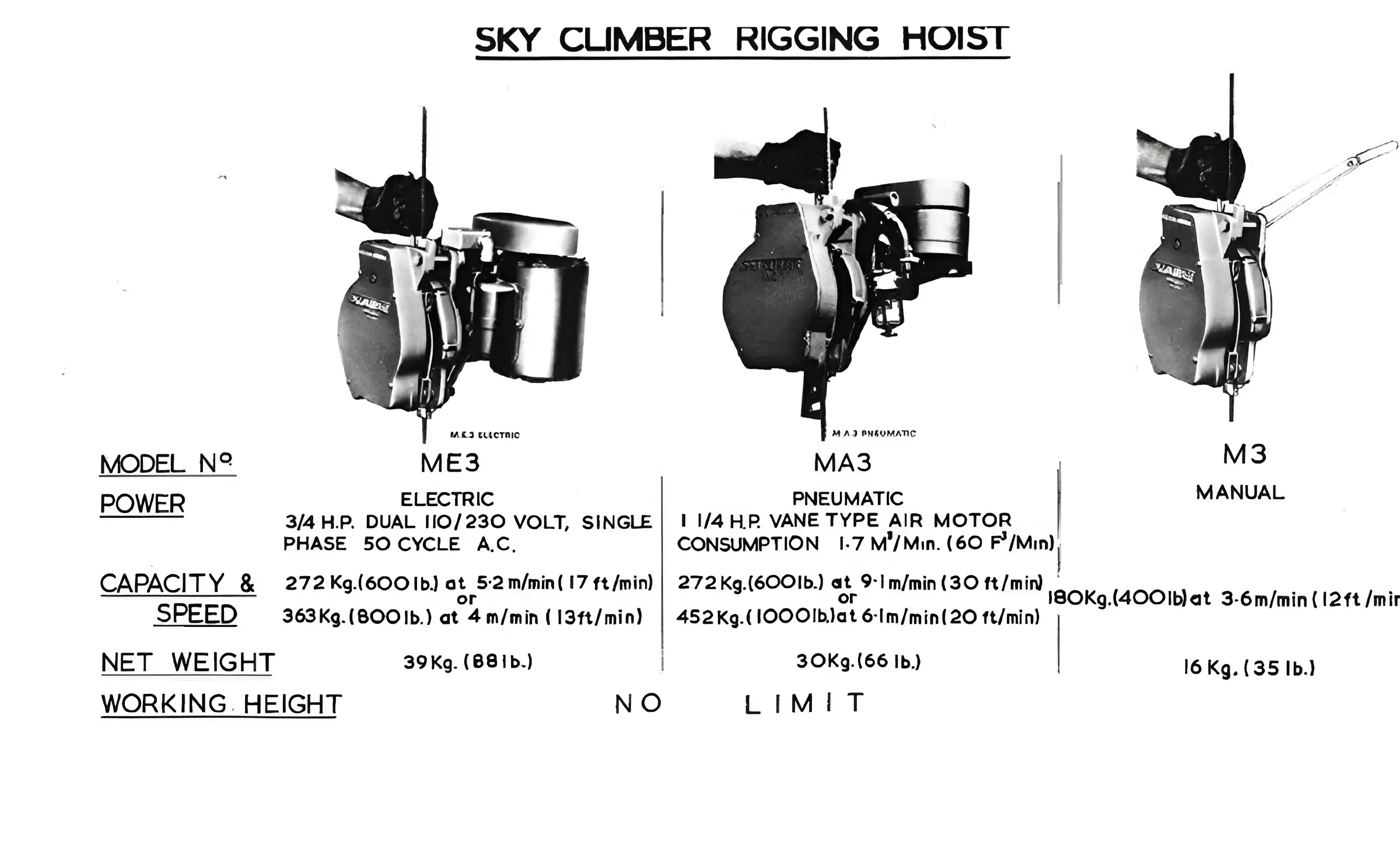

In the 1950s, engineers at Western Gear saw an opportunity – modify their man-rated rescue hoist into a powered suspended scaffold hoist—creating what would become the M3. That singular idea launched the powered suspended access industry.

The M3 model—later followed by the ME3, MA3, and others—was the first of its kind. Though the equipment has evolved drastically since then, the same DNA of innovation still drives the Sky Climber brand today.

“We didn’t just create a product—we created an industry.”

Jean-F. De Smedt, Managing Director, Sky Climber Europe

Western Gear Corporation’s man-rated rescue hoist—inspiration for its future powered access systems.

Built for the Job. Trusted Around the World.

Sky Climber products have helped construct, maintain, and restore iconic structures—from skyscrapers to stadiums, turbines to transit systems. Today, our equipment supports a wide range of industries, including building construction and maintenance, infrastructure and bridge access, power generation facilities (wind and hydro), civil engineering, specialty rigging, art installations, and historic preservation.

While equipment has grown smarter, safer, and more specialized, one thing has remained unchanged: Sky Climber’s commitment to delivering engineered access solutions that customers can count on.

“Our customers don’t just buy equipment—they depend on us to help solve complex access challenges with safety and precision.”

“That’s why we continue to invest in people, processes, and product development.”

Kelly Winkler, President & CEO

A Global Footprint, with Local Relationships

From its early U.S. operations in Lynwood, California, to the strategic relocation to Stone Mountain, Georgia, and later expansion into Belgium and beyond, Sky Climber’s growth has always been built on relationships. The company’s European division, Sky Climber Europe (SCE), officially opened its first factory in 1970. Today, Sky Climber serves clients on six continents with regional expertise and global reach.

Western Gear Europe and Sky Climber Europe—1970—Kontich (Antwerp) of Belgium

Sky Climber manufacturing facility in Stone Mountain, GA—1980s

“Our ability to offer customized solutions—from monorail systems to modular platforms—has helped us remain the go-to partner, even as low-cost manufacturing emerged through the years.”

“In fact, today, engineered specials now represent a significant portion of our European business.”

Kristof Rombouts, General Manager of Sky Climber Europe.

Sky Climber Europe manufacturing facility in Duffel, Belgium—2025

Sky Climber U.S. manufacturing facility in Delaware, Ohio—2025

People, Safety, and Purpose

At the core of Sky Climber’s success are its people. From long-tenured engineers to rising talent, the culture emphasizes collaboration, craftsmanship, and customer commitment. Every product is backed by a dedication to safety—not just in design, but in training, support, and field application.

“From our R&D teams to the shop floor, every person here understands their role in helping others work safely at height. That mindset shows up in the quality of every system we produce.”

Chris Ogden, VP of Engineering & Operations

The Next Chapter of Innovation

Looking ahead, Sky Climber is actively investing in future-facing solutions. Whether through smart integration, enhanced digital controls, or sustainability-focused designs, the next generation of access equipment is already in motion.

From supporting the energy transition to addressing evolving infrastructure needs, Sky Climber is poised to lead.

“As access demands grow more complex—whether in energy, transit, or urban infrastructure—our role is to stay ahead of the curve. We’re focused on what’s next.”

“Seventy years is a significant milestone. But for us, it’s just the beginning of our next climb.”

Kelly Winkler, President & CEO

Share the Story

Want to help us celebrate 70 years of innovation? Download our media kit or grab the full asset pack below.

Media Inquires: