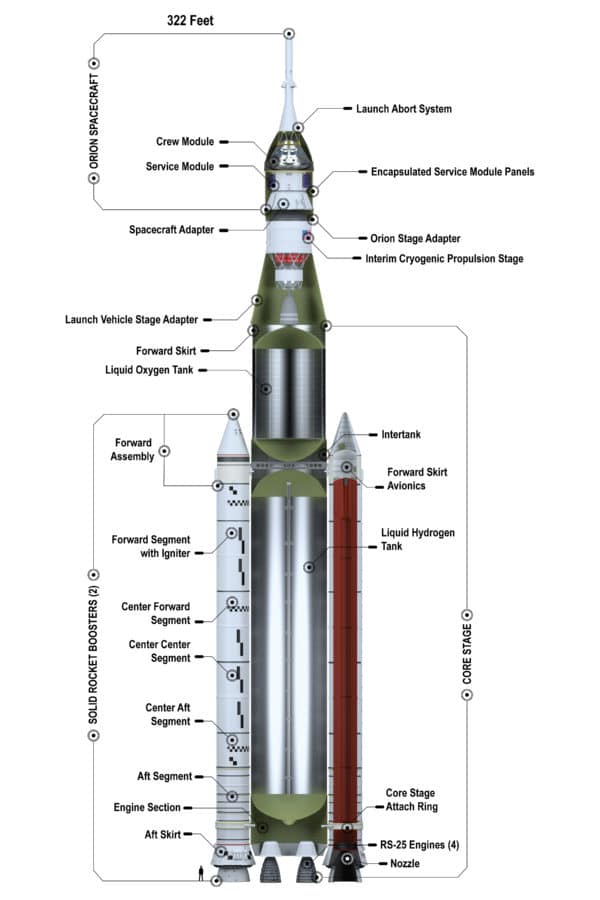

NASA’s Space Launch System (SLS) rocket is an advanced, heavy-lift launch vehicle that will provide an entirely new capability to science and human exploration beyond earth’s orbit. It is being designed to carry Orion spacecraft on missions to explore deep space and is slated to be the most powerful rocket in history.

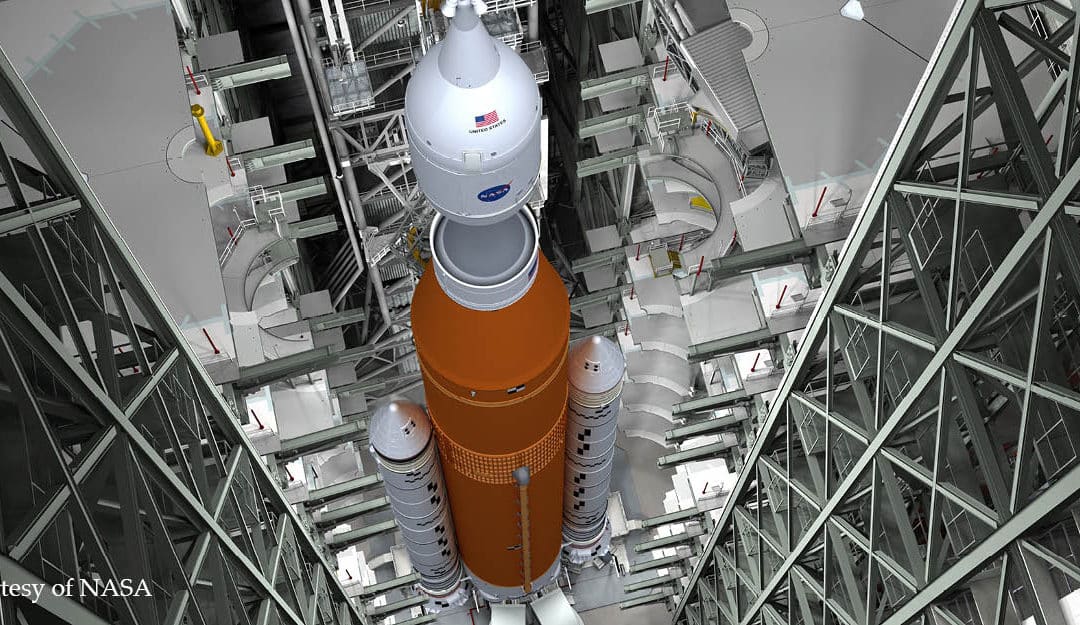

Sky Climber had the opportunity to design a special hoist system to be used during the construction and testing of “Core Stage” elements, including liquid hydrogen and oxygen fuel tanks.

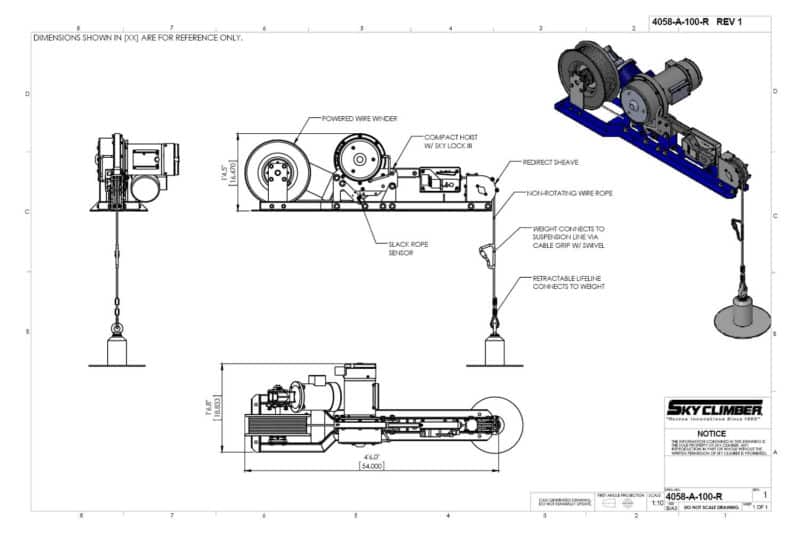

During assembly and testing phases of the Core Stage, workers need to be lowered into fuel tanks from above. To maintain a “clean room” level of sanitation and particle control, three Sky Climber Compact Hoists were mounted in a secure compartment above the assembly area in NASA’s Michoud facility in New Orleans, Louisiana.

The hoists feature horizontal mounting brackets and special wire rope that, together with a vacuum system, keep the workspace free of debris and small particles that could potentially damage the tanks below. The hoist system provides safe personnel access to the interior of rocket tanks as they are assembled and inspected vertically at the state-of-the-art manufacturing center at Michoud.

The overall hoist system included three Compact Electric hoists, remote mounted hoist controls, powered wire winders, SkyLock IIIs, redirect sheaves, stainless steel non-rotating wire rope and custom horizontal mounting brackets. With the hoist motors and redirect sheaves mounted overhead, workers wearing climbing harnesses can be lowered through narrow openings at the top of the tanks.

For more information on the SLS rocket, check out NASA’s webpage and YouTube channel for fact sheets and articles.