Tower Applications

Propane-powered Painting Platform

The operators of a massive antenna system required a special access solution for a painting project and Sky Climber was happy to help.

The antenna system consists of more than a dozen steel towers, some reaching nearly 900 feet in height. To paint these structures, crews needed a way to not only reach the structure but to also provide a power source at that height. Traditional electrical cords lose power incrementally over every foot of cord distance, and at 900 feet, the loss of voltage would be enough to eliminate ground-sourced power as an option.

Instead, Sky Climber Engineers developed two propane-powered platform systems that solved the electricity problem. Each system used three independently-operated platforms, one for each side of a tower. Each 3-meter SSU platform incorporated two 3-phase LNX 1500 hoists, low-profile stirrups, secondary SkyLocks, and custom Central Control Boxes (CCBs). The CCBs controlled the platform movement and the power generators which were tucked under the main platform walkway. The propane-fueled power generators, similar to those used in forklifts, provided reliable power and allowed crews to perform their tasks safely, even at 900 feet.

This design is ideal for truss-built tower projects and applications where extreme height or depth make access to electricity a challenge.

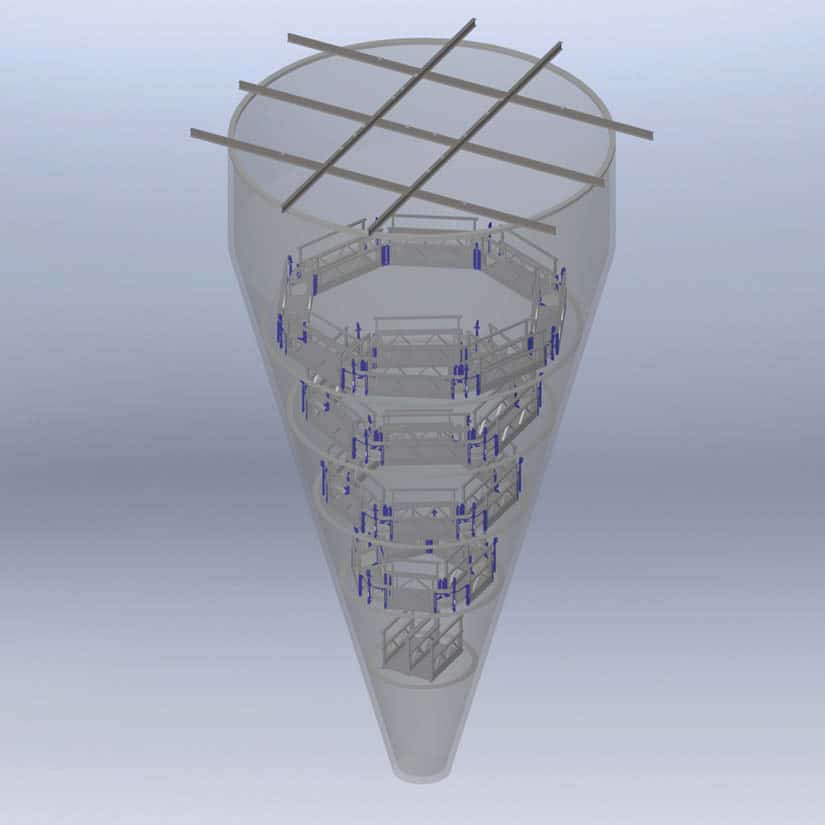

Access system for stack tower

The Total Fina Olefins Flares in Antwerp are supported in a steel lattice mast and are some of the tallest structures in Belgium (up to 211m high). The Total Fina Flares in the Port of Antwerp are used for burning off flammable gas in the Total refinery.

In order to inspect, maintain and repair the flare stacks, Sky Climber designed and manufactured a rigging and access solution which allows technicians to go up and reach each and every point of the steel lattice of the mast. Time is one of the most critical elements during maintenance, as shutdown time must be kept to a minimum. Sky Climber designed an easy to install Light Weight Cage, which can be used for accessing any point around and even inside the lattice structure of the mast by using standard steel wire ropes and a deviator cable with a manual winch. The deviator cable pulls the cage to the side in order to deviate the cage from a standard vertical descent and allow the cage to be directed to the place that needs to be reached.

Water Tower renovation and painting

The Dutch city of Schoonhoven is renowned for its silver and is nicknamed “Zilverstad” (Silver City). The very picturesque water tower, the most beautiful in the Netherlands, dominates the cityscape. Constructed in 1901, it was used as a water tower until 1982. After extensive renovations in 1996, the water tower was turned into a Gallery for Silversmiths and Silver Art.

This summer, a new round of renovations was required and instead of using traditional tubular scaffolding, the contractor opted for a circular workspace created by Sky Climber Light Weight Stage platforms with: angle sections, four walk-though stirrups and four Alpha 500 traction hoists. The suspension arms were installed inside the tower and the jibs were extended out by making small (temporary) openings in the façade wall.

This circular work platform allowed the people working on the platform to have excellent access to the full circumference of the water tower in order to make sure that this monument of National Heritage remains the pride of the city!

More Tower applications

Whether you are preparing to scale a communication tower, a lighthouse, airport control tower, or other industrial structure, Sky Climber can provide standard and custom solutions to safely carry inspectors and maintenance crews wherever they need to go.

View our Engineering Gallery for ideas or Contact Us for more information.