Civil and Infrastructure Access

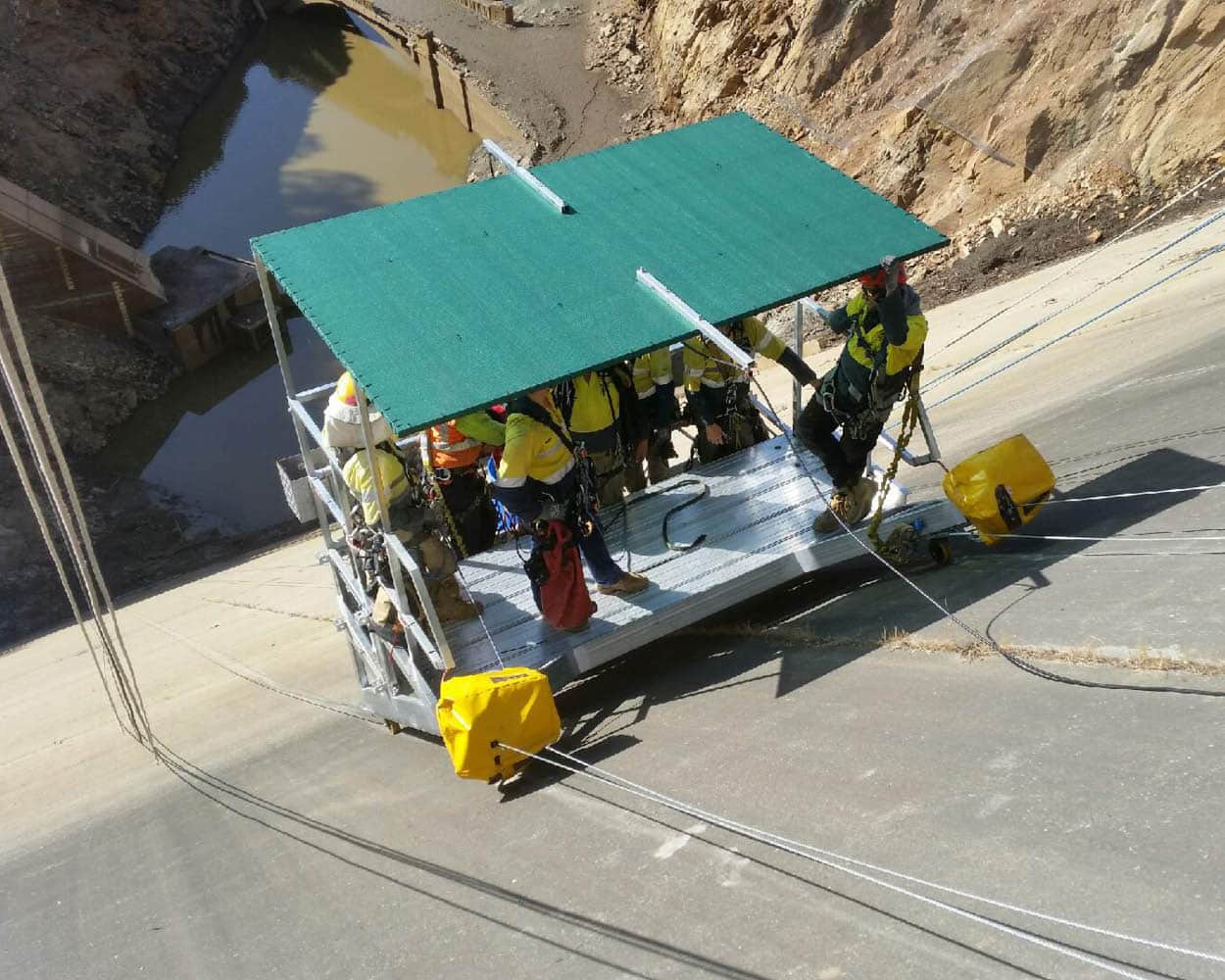

Angled Rolling Platform for Australian Dam

Kangaroo Creek Reservoir is an artificial water storage reservoir in the Adelaide Hills, South Australia. The dam was built in 1969 and is 131m long and 65m high.

Although Kangaroo Creek Dam has performed satisfactorily since completion, changes to dam safety standards have meant that upgrade works were required to meet current criteria for resistance to seismic loading and flood capacity.

Sky Climber Europe provided a cost saving access solution by supplying four custom designed rolling platforms made from standard Sky Stage Ultra components. The platforms allowed inspection and upgrade works to be carried out on all areas of the dam while the entire dam remained fully operational.

The extra wide floor with two split levels allowed people on the platforms to access the slope of the dam and do the necessary inspection, remedial and upgrade works.

Alpha 500 hoists were used to allow the platforms to roll up the entire height of the dam. Special floating bottom trip limit switches were installed to prevent the platforms from going down into the water.

Cofferdam Access on Dam Crossing

The engineering plan to rehabilitate trash racks on the Conowingo Hydroelectric Generating Station incorporated one of the deepest asymmetrical cofferdams ever built or used in the United States. At 100 feet tall, the cofferdam required a custom suspension system to safely carry workers through the tube as they replaced sections of track set into the dam’s façade.

The platforms needed to conform to exact specifications within the cofferdam structure, providing ample space for workers and equipment. Other requirements included a guide system, lift mechanisms, and the ability to move the lift system between cofferdam installations. Beyond the basic scope of requirements for the equipment, Sky Climber delivered several system features that added value for the customer. The resulting system was safer, lighter, easier to install, and simple to use. Sky Climber systems provided safe access for workers for twenty hours a day throughout twenty weeks of construction.

Sky Climber’s contribution to this project earned a 2018 Project of the Year Award from the Scaffold and Access Industry Association (SAIA) for Suspended Access projects.

OARS Deep Tunnel Access

As part of an agreement with the State of Ohio, the City of Columbus built a massive tunnel to reduce combined sewer overflows and their environmental impacts during flood events. The tunnel project, dubbed OARS, was designed to intercept wet weather overflows that would otherwise empty into the Scioto River in the heart of Columbus and instead carry the flows to wastewater treatment plants.

Construction officials required Sky Climber’s help to access the largest maintenance shaft during several construction phases of installing pipes and bracing for the pipes in and around different areas. Sky Climber provided a system of permanently-installed rigging equipment for use during construction and for later routine maintenance. The system includes a manned work platform, davit bases with embed cages around the opening of the shaft and 2 movable top rotating davits. The 3-meter platform was powered by Compact air hoists as main travel hoists and separate Compact Air rescue hoists as an emergency rescue system.

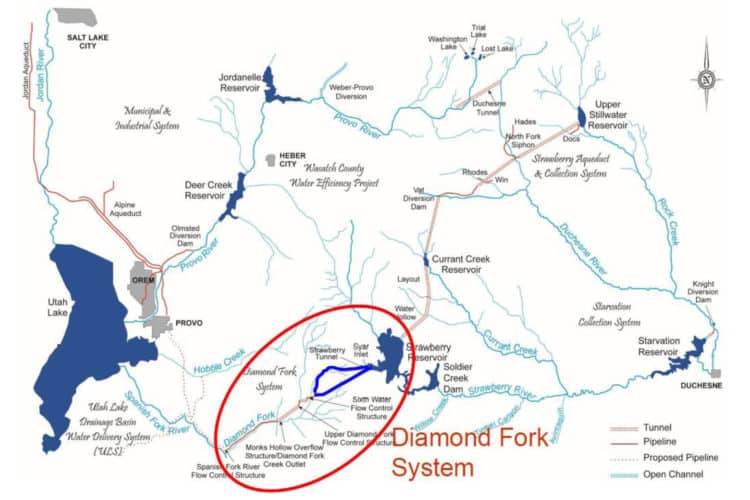

Deep tunnel access at Strawberry Reservoir

The Strawberry Aqueduct and Collection System (SACS) is a system of reservoirs, tunnels, pipelines, and diversion dams designed to collect and distribute water throughout Utah.

The Strawberry Reservoir is an important part of this system. It directs water via a pipeline and tunnel system buried hundreds of feet deep in the mountains along the Continental Divide. Massive valves positioned where the pipeline transitions to an open tunnel require routine maintenance and inspection. To access these valves, workers must descend through a 30’’-wide vertical shaft from a remote mountaintop location.

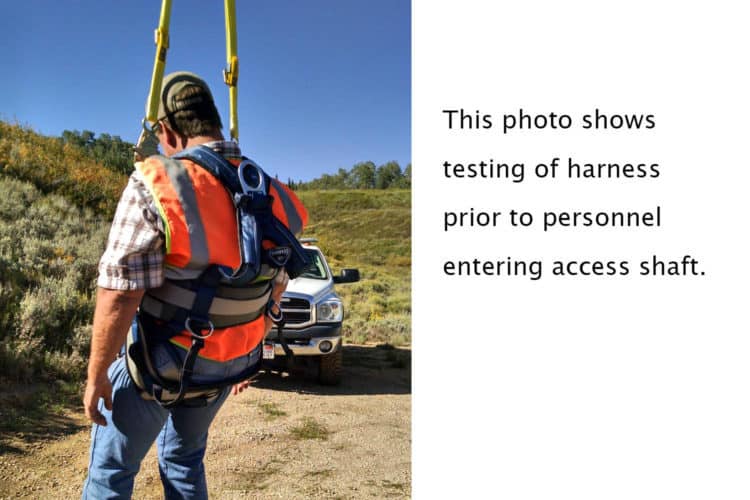

In 2014, authorities sought to find a safe access solution for this scenario. Sky Climber provided consultation services, surveying the location and requirements and providing recommendations on a solution that complied with American National Standards Institute / American Society of Safety Engineers (ANSI/ASSE).

Based on report findings the customer then turned to Sky Climber again to provide a personnel hoist system for the Strawberry Tunnel access shaft.

The final design utilized two horizontally-mounted hoists, passive wire winders, SkyLocks, redirect sheaves, and custom mounting brackets. With this system, wire rope is positioned directly over the shaft opening with redirect sheaves. Workers are suspended with climbing harnesses and can be lowered into the narrow shaft until they reach the tunnel 200 feet below.