Port and Maritime Solutions

Grain Barge Access for Inspections

As the brewing industry in Ohio continues to grow, related industries are busy supplying the materials used in beer production. Grain and transportation companies busily traverse the Ohio river in Cincinnati, using barges to transport mountains of grains to beer production facilities.

Sky Climber recently supplied a grain distribution company with a barge access system which allows operators to lower workers onto unmanned barges for inspection and maintenance. A Compact Electric Hoist was installed to control the ascent and descent of an existing workcage. Sky Climber also provided new controls for the workcage so that the rider can control its movement in addition to the tower operator. Click the button below to download a case study for a similar project in New Orleans.

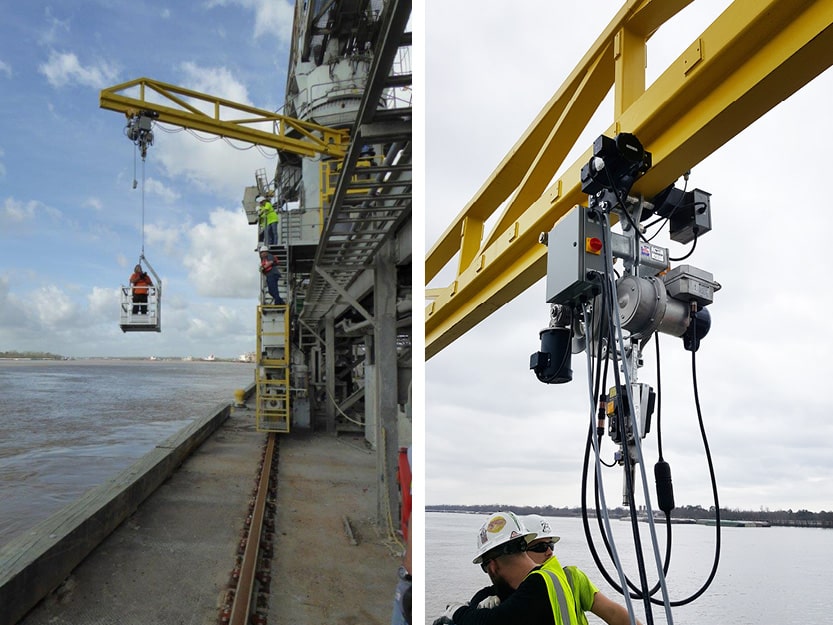

Powered Trolley and Workcage for Barge Access

Built for an international cement company, this powered trolley, wire winder, and workcage system is ideal for use in many scenarios. For this project, the customer needed a new solution to repeatedly transport workers from a busy marine terminal structure down over the river and onto floating barges for inspection and maintenance.

Sky Climber product teams developed a system based on a Compact Electric Hoist, powered trolley, wire winder, and work basket that would work with an existing jib beam. The system allows workers to traverse the length of the rotating beam, downward into the barge and then back up. This user-friendly configuration makes routine barge inspections safer and is versatile enough to use in a variety of other applications.

Dockside Rescue Lift

The Kieldrecht Lock is the world’s largest lock and gives access to the left-bank docks of the Port of Antwerp in Belgium. The new lock is at the end of the Deurganck dock, the biggest tidal dock in the world.

Sky Climber designed, manufactured and installed at the entrance of the Kieldrecht Lock a 24/7 stand-by dismemberment / rescue platform to bring injured people lying on a stretcher on land.

The system is using a hydraulic mechanism to swing the platform over the quayside and uses a drum winch to travel up and down. The platform is equipped with all possible safety features to ensure safe operations and to avoid the platform touching the tidal water. The entire setup is designed to work in a saline marine environment.

Harbour Light with Helicopter Platform

Download the case study of a Harbour Light with Helicopter Platform renovation that required Sky Climber Platforms for concrete repair work.

Shipyard Monorail Application

Check out the details of a Shipyard application that used Sky Climber monorail systems to access a ship’s hull for anti-corrosion treatment and painting.

Ship-to-shore Crane Repair

Read the case study of a large custom platform used to access and replace the festoon cable of a ship-to-shore crane for the Georgia Port Authority.