Improving cement barge inspections at industrial import facility

Built for an international cement company, this powered trolley, wire winder, and workcage system is ideal for use in many scenarios.

For this project, the customer needed a new solution to repeatedly transport workers from a busy marine terminal structure down over the river and onto floating barges for inspection and maintenance.

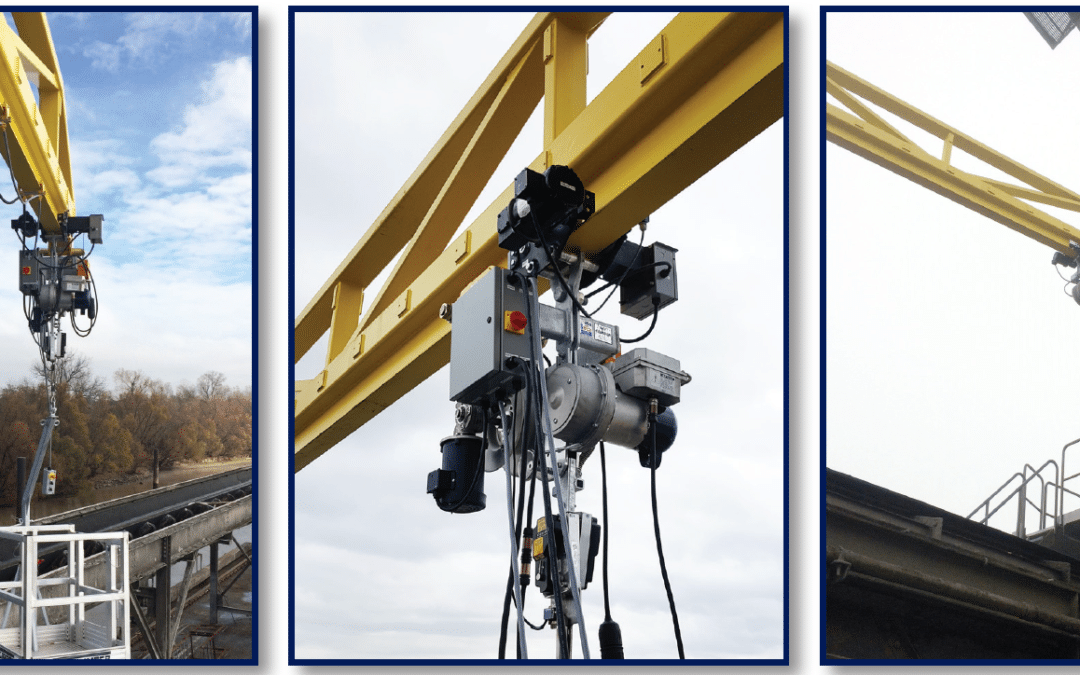

Sky Climber product teams developed a system based on a Compact Electric Hoist, powered trolley, wire winder and work basket that would work with an existing jib beam. The system allows workers to traverse the length of the rotating beam, downward into the barge and then back up. This user-friendly configuration makes routine barge inspections safer and is versatile enough to use in a variety of other applications.

Safe, versatile

Prior to the development of this system, the customer used non-OSHA compliant ladders, and non-man-rated air tuggers to raise and lower workers in and out of the barges. This made routine inspections, cleaning and maintenance work hazardous and unsafe.

This system utilizes an OSHA-compliant Compact Electric Hoist, which allows the Operator / Rider to control the hoist with a wireless remote. Plus, with our patented Sky Lock technology and emergency descent feature for lowering during power failure, this system makes traversing in and out of barges and other vessels considerably safer.

Additional applications

This barge access powered trolley system is ideal for any ship-hold or barge inspection applications. Each time a cargo hold is emptied before refilling, whether with cement, gravel, sand, grain, etc., this system will quickly and safely deliver workers to and from the vessel with ease.